Brand: Virnig

SKU: DRM60VS-DRM60TKS

Heavy-duty skid steer drum mulcher designed for serious land clearing and stump grinding. The Virnig V70 Drum Mulcher turns trees up to 14″ into fine mulch, grinds stumps below grade, and offers fixed or variable speed piston motor options. Built strong with a balanced QUADCO® drum, replaceable tooth styles, and reinforced wear parts for long-lasting use.

Virnig V70 Drum Mulcher for Skid Steer

Brand: Virnig

|SKU: DRM60VS-DRM60TKS

Heavy-duty skid steer drum mulcher designed for serious land clearing and stump grinding. The Virnig V70 Drum Mulcher turns trees up to 14″ into fine mulch, grinds stumps below grade, and offers fixed or variable speed piston motor options. Built strong with a balanced QUADCO® drum, replaceable tooth styles, and reinforced wear parts for long-lasting use.

Free Shipping On Orders Over $5000

Free Shipping On Orders Over $5000

30 Days Satisfaction Guarentee

30 Days Satisfaction Guarentee

Easy Financing Available Here

Easy Financing Available Here

-

Description

v70 Drum Mulcher

Skid Steer Drum Mulcher

Efficiently turn 14″ diameter trees and vegetation into a fine mulch and grind stumps below grade.

- FIXED & VARIABLE SPEED BENT-AXIS PISTON MOTOR OPTIONS. VARIABLE MOTOR PROVIDES MORE TORQUE FOR PRODUCTIVE STUMP GRINDING & MULCHING BELOW GRADE

- FACTORY TUNED TO THE LOADER FOR OPTIMAL DRUM RPM — NO MOTOR ADJUSTMENT OR SERVICE TECHS REQUIRED

- 18″ PERFECTLY BALANCED QUADCO® DRUM WITH FULLY ENCLOSED GREASEABLE BEARINGS

- ANTI-WRAP DRUM PLATES PROVIDE WIRE & DEBRIS ENTANGLEMENT PROTECTION

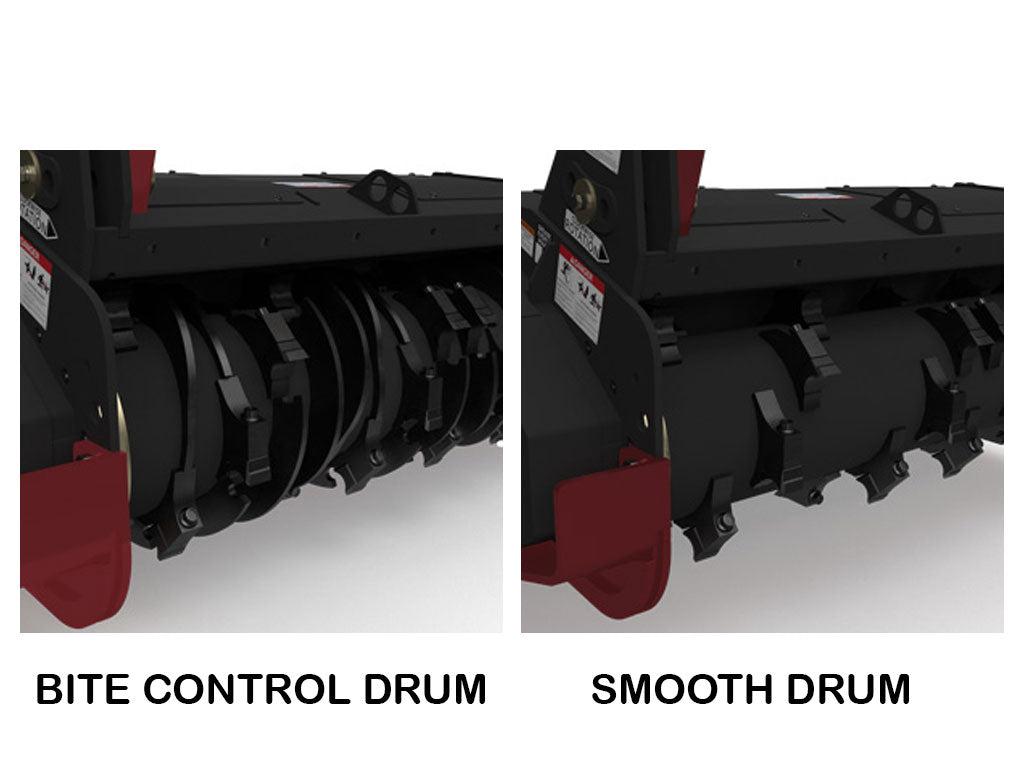

- INTERCHANGEABLE QUADCO® BOLT-ON STEEL & CARBIDE TOOTH OPTIONS

- AR400 BOLT-ON SKID SHOES, ADJUSTABLE PUSH BAR & REPLACEABLE AR400 WEAR LINER

- ADJUSTABLE BOTTOM BITE PLATE TO CONTROL MATERIAL DISCHARGE SIZE

- SPINDLE LOW PRESSURE OIL VENT SAFEGUARDS BEARING ADAPTER SEALS IF MOTOR SEALS FAIL

- CASE DRAIN CONNECTION INDICATOR PROVIDES VISUAL CONFIRMATION OF FUNCTIONING CASE DRAIN

- REAR CHAIN CURTAIN REDUCES DEBRIS THROWN TOWARD LOADER & OPERATOR

Requires a high flow loader with a flow rate of 30-50 GPM. Max operating pressure is 4,200 PSI.

SPECS

MODEL DRM60 DRM72 Cut Width (Inches) 60.0 72.0 Overall Width (Inches) 73.0 85.0 Height: Overall / Frame (Inches) 59.8 / 25.0 Depth: Overall / Frame (Inches) 57.5 / 41.3 Push Bar Height From Ground (Inches) 58.2 Cutting Capacity, Diameter (Inches) 14.0 Maximum Cutting Depth (Inches) 2.0 Number of Teeth 34 38 Maximum Drum Speed (RPM) 2500 (+/- 150 RPM) Drum Diameter (Inches) 18.0 Drum Wall Thickness (Inches) 1.0 Recommended Flow Rate (GPM) 30-50 High Flow Only Approximate Weight With Smooth Drum (Pounds) 2735* 3010* Recommended Loader Capacity Greater than 2800 pounds *60″ bite control drum adds 130lbs and 72″ bite control drum adds 155lbs to model weight.

BLADE TIP SPEEDS (FPM)

HIGH FLOW MODEL

MODEL Min / Max Drum Speed (feet per minute) DRM 11,075 / 12,500 WHAT CUTTING WIDTH SHOULD I CHOOSE?60” drum mulchers are more popular since they’re more maneuverable in tight spaces, draw less HP from the loader and spin up and recover faster than a 72” drum mulcher. When primarily clearing trees, most of the production occurs in the middle of the drum and having an extra foot of cutting width isn’t necessary.

72” drum mulchers process more material at a faster rate than a 60” drum mulcher This can be an advantage when working on larger job sites with a lot of ground vegetation to clear and where significant back dragging and ground mulching is required. The heavier drum handles larger material loads and provides more cutting momentum when grinding stumps and through thick vegetation. 72” drum mulchers are more expensive upfront and will likely cost more to operate and maintain.

HOW DOES A DRUM MULCHER COMPARE TO A DISC MULCHER?They both have advantages and disadvantages. Typically, drums are used in residential areas and discs used in unrestricted, rural areas with no houses or traffic. If flying debris is a concern, then a drum should probably be used. If the customer doesn’t care about the finished product and are in an unrestricted area, then a disc mulcher is usually preferred.

Discs are for speed and are much more productive and efficient for cleared area/time. They can process an entire tree in a split second and the mulched material doesn’t pile up.

Drums are more productive at processing felled material, leave less mess during initial knock down, produce a finer mulched finish and have better debris control.

Drums can get below ground level (great for stumps), discs can cut flush with the ground.

Quick Comparison Summary

- Drum = Quality: slower, nicer finish, some debris control, diverse environments, mulch below grade, higher operating cost, more expensive upfront cost

- Disc = Speed: faster, messier finish, debris uncontrollable, unrestricted environments, mulch ground level, lower operating cost, less expensive upfront cost

SPEC COMPARISONS - VIRNIG MULCHERS

Easily compare Tree Disc Mulcher (TDM) and Drum Mulcher (DRM).

V70 Tree Disc Mulcher (TDM)

- Width(s): 60"

- Cut Capacity (Dia.): 14"

- Productivity: Faster

- Finish: Wood Chunks

- Environment: Rural

- Stump Grinding: Ground Level

- Cost: Lower

- Maintenance: Less

- Tooth Qty: 44

- Disc / Drum Weight: 900 lbs.

- Rec. Loader Capacity (lbs): > 2,800

V70 Drum Mulcher (DRM)

- Width(s): 60" & 72"

- Cut Capacity (Dia.): 14"

- Productivity: Slower

- Finish: Fine Chips

- Environment: Residential

- Stump Grinding: 2" Below Grade

- Cost: Higher

- Maintenance: More

- Tooth Qty: 34 / 38

- Disc / Drum Weight: 750-1,030 lbs.

- Rec. Loader Capacity (lbs): > 2,800

SHOULD I CHOOSE A FIXED MOTOR OR A VARIABLE MOTOR?The Fixed Speed Bent-Axis Piston Motor (63cc max displacement) is the less expensive option for lighter vegetation and brush removal above ground. It will stall easier than a variable motor during heavy material loads, like when grinding stumps or mulching below grade, since it has less torque.

The Variable Speed Bent-Axis Piston Motor (85cc max displacement) is the most popular motor due to productivity gains when stump grinding and ground mulching. During heavy material loads, the motor smoothly shifts to max displacement and a slower speed to provide more torque.

WHICH TOOTH OPTION SHOULD I CHOOSE?There are three tooth options which can be mixed and matched on the drum. The optimal choice depends on ground conditions, ground contact required and chip size requirements.

Steel planer teeth are the most productive and provide the smallest and finest mulched finish. They can be resharpened and rotated 180 degrees for twice the life.

Carbide Planer teeth are a hybrid between the steel planer and carbide hammer. It provides high productivity and can handle minimal ground contact.

Carbide Hammer teeth are for significant ground engagement and will provide the largest chip size. They also require the most loader power to operate since they are pulverizing material instead of slicing and cutting.

Steel Planer

- For max productivity and the finest mulch without ground contact

- Have two razor sharp edges to quickly slice through wood and pick up material off the ground

- Made from high-grade alloy steel and heat treated

- Reversible and need to be sharpened regularly to maintain high production

- Stay off the ground and out of sand with steel teeth or the edges will dull quickly

Carbide Planer

- Sharp cutting angle and curved body profile for higher productivity than hammer teeth with minimal ground contact

- Requires no maintenance – no sharpening required

- Abrasion resistant carbide tips for durability in rocky & sandy environments

- Produce slightly larger wood chips than steel planer with similar productivity

Carbide Hammer

- For significant ground engagement in rocky and sandy conditions, less productive than planer teeth

- Produces largest mulch and the least amount of ground suction – pulverizes and rips material instead of cuts

- Requires no maintenance – no sharpening required

- Ideal option if mulcher is primarily used to mix mulch into the soil

- Most abrasion resistant option with lowest cutting performance and productivity

- Requires more power from the loader to operate

-

Payment & Security

Secure Payment Options

We prioritize your security and ensure that every transaction is protected. We offer multiple secure payment methods including:

- Visa, MasterCard, American Express, Discover

- A fast and secure payment method accepted globally

- For quicker checkout on mobile devices

- Integrated with Shopify's secure payment gateway

Encryption & Data Protection

Your privacy and security are our top priority. We use SSL encryption to protect your personal information and payment details. This ensures that all communication between your browser and our server is encrypted and secure.

We also adhere to PCI-DSS standards, which are industry guidelines for managing payment card information securely. Rest assured, your payment information is never stored on our servers.

Fraud Prevention

To ensure that our customers' transactions are secure, we use advanced fraud detection systems. This helps protect both the store and our customers from fraudulent activity.

Privacy Policy

For more information on how we collect, use, and protect your data, please review our Privacy Policy.

-

Shipping & Delivery

Shipping Methods

We offer a variety of shipping options to ensure that your order reaches you as quickly and securely as possible

- Delivery within 5-7 business days.

- Delivery within 2-3 business days for a faster option.

- Get your order the very next day, available for select locations.

- We offer shipping to several countries. Delivery times vary depending on the destination.

Order Processing

- Orders are processed within 1-2 business days after receiving your order confirmation.

- Orders placed on weekends or holidays will be processed on the next available business day.

- You will receive an email with tracking information once your order has shipped.

Delivery Times

- Delivery times are estimated and may vary depending on your location.

- Orders shipped to remote areas may experience slight delays.

- For international deliveries, customs processing times may affect delivery times.

Order Tracking

Once your order has shipped, you will receive a tracking number via email. You can use this tracking number to monitor the progress of your shipment on the carrier’s website.

Lost or Damaged Packages

- If your order is lost or damaged during shipping, please contact us within 7 days of the delivery date.

- We will work with the carrier to resolve the issue and either offer a replacement or issue a refund.

Contact Us

If you have any questions about shipping, delivery, or need assistance tracking your order, please contact our customer service team at support@skidsteerstore.com

Virnig V70 Drum Mulcher for Skid Steer

See the Virnig V70 in Action

Key Features

-

14″ Tree Capacity – mulches trees up to 14″ in diameter and grinds stumps 2″ below ground.

-

Motor Options – choose between Fixed Speed (lighter jobs) or Variable Speed (more torque for stumps & heavy mulching).

-

Balanced 18″ QUADCO® Drum – smooth operation with enclosed greaseable bearings.

-

Interchangeable Tooth Options – Steel Planer, Carbide Planer, or Carbide Hammer teeth.

-

Durability Built In – AR400 bolt-on skid shoes, push bar, wear liner, and anti-wrap plates for long life.

-

Safety First – rear chain curtain reduces debris thrown toward the operator.

-

Custom Finish – adjustable bottom bite plate to control mulch size.

-

Loader Ready – factory tuned to loader, no adjustments needed.

Detailed Description

The Virnig V70 Drum Mulcher is built for contractors and landowners who need powerful mulching and stump grinding performance. Its 18″ QUADCO® drum is perfectly balanced for smooth operation and fitted with interchangeable tooth styles depending on your needs:

- Steel Planer Teeth for fastest cutting and finest mulch finish.

- Carbide Planer Teeth for durability with some ground contact.

- Carbide Hammer Teeth for heavy ground work, rocky soil, and largest mulch size.

With a cutting capacity of 14″ trees and the ability to mulch stumps below grade, the V70 Drum Mulcher is ideal for residential clearing, right-of-way work, and site preparation.

The design includes replaceable wear parts, skid shoes, adjustable push bar, chain curtain for safety, and an adjustable bottom bite plate for mulch size control.

Choose between Fixed Speed Motor for lighter brush work or Variable Speed Motor for more torque when grinding stumps.

Available in 60″ (maneuverable) or 72″ (higher production) sizes, the V70 Drum Mulcher adapts to your skid steer’s hydraulic flow for maximum efficiency.

Why Choose the Virnig V70 Drum Mulcher?

-

Handles large jobs: mulches trees up to 14″ & grinds stumps below ground.

-

Multiple tooth options for different terrains and finishes.

-

Replaceable wear parts = lower long-term costs.

-

Choice between 60″ (maneuverable) or 72″ (high production).

-

Safe and operator-friendly with rear chain curtain and anti-wrap plates.

VIRNIG V70 Drum Mulcher Specifications

Frequently Asked Questions

You’ll need a high-flow skid steer with 30–50 GPM and over 2,800 lbs lift capacity.

- Fixed: Lower cost, good for brush and lighter work.

- Variable: More torque, better for stumps and below-grade mulching.

- Steel Planer: Fastest cutting, fine mulch (no ground contact).

- Carbide Planer: Good mix of speed and durability, some ground contact.

- Carbide Hammer: Heavy ground use, rocky soil, biggest chips.

- 60″: More maneuverable, faster recovery, better in tight spaces.

- 72″: Clears more ground faster, better for large sites, heavier upfront cost.

- Disc: Faster, rougher finish, best for open rural areas.

- Drum: Slower, finer mulch, safer in residential or controlled areas.

Approx. 2,735 lbs (60″) and 3,010 lbs (72″).

Shop by Equipment

Before and After Stories Directly From Our Customers

“This drum mulcher is a beast. I run the 72″ with variable motor and it doesn’t slow down, even on 12–14″ hardwoods. The finer mulch it leaves behind is perfect for residential jobs.”

“I went with the 60″ because of tighter areas on my property. Easy to maneuver, powerful, and the steel teeth cut like crazy. Clears fence lines fast.”

“Very strong attachment. I only gave 4 stars because it’s heavy—you really need the right skid steer. But performance is excellent, especially for stump grinding.”

“The variable speed motor was worth every penny. When I hit tough stumps, it shifts into torque mode and powers through. Maintenance is straightforward too.”

“Best mulcher I’ve owned. Durable build, replaceable wear parts, and the adjustable bite plate helps me control mulch size. Highly recommend it.”

Skid Steer Store | Your Heavy Equipment Attachment Headquarters

- Choosing a selection results in a full page refresh.

- Opens in a new window.

3 Point Hitches

3 Point Hitches

Anchor Drives

Anchor Drives

Augers

Augers

Backhoes

Backhoes

Bale Spears

Bale Spears

Booms

Booms

Brooms

Brooms

Brush Cutters

Brush Cutters

Buckets

Buckets

Cold Planers

Cold Planers

Dozer Blades

Dozer Blades

Feller Bunchers

Feller Bunchers

Flail Mowers

Flail Mowers

Graders

Graders

Grapples

Grapples

Harley Rakes

Harley Rakes

Mulchers

Mulchers

Pallet Forks

Pallet Forks

Post Drivers

Post Drivers

Snow Pushers

Snow Pushers

Stump Grinders

Stump Grinders

Tree Pullers

Tree Pullers

Tree Saws

Tree Saws

Trenchers

Trenchers

Augers

Augers

Backhoes

Backhoes

Booms

Booms

Brooms

Brooms

Brush Cutters

Brush Cutters

Buckets

Buckets

Dozer Blades

Dozer Blades

Graders

Graders

Grapples

Grapples

Mulchers

Mulchers

Pallet Forks

Pallet Forks

Power Rakes

Power Rakes

Snow Pusher

Snow Pusher

Trenchers

Trenchers

Augers

Augers

Breakers

Breakers

Brush Cutters

Brush Cutters

Buckets

Buckets

Couplers

Couplers

Feller Bunchers

Feller Bunchers

Grapples

Grapples

Mulchers

Mulchers

Pallet Forks

Pallet Forks

Plate Compactors

Plate Compactors

Post Drivers

Post Drivers

Rippers

Rippers

Stump Grinders

Stump Grinders

Thumbs

Thumbs

Tree Saws

Tree Saws

Trenchers

Trenchers

Augers

Augers

Breakers

Breakers

Brush Cutters

Brush Cutters

Buckets

Buckets

Mulchers

Mulchers

Rippers

Rippers

Stump Grinders

Stump Grinders

3-Point Adapters

3-Point Adapters

Augers

Augers

Auxiliary PTO Pumps

Auxiliary PTO Pumps

Brooms

Brooms

Brush Cutters

Brush Cutters

Buckets

Buckets

Dozer Blades

Dozer Blades

Generators

Generators

Graders

Graders

Grapples

Grapples

Hay Grapples

Hay Grapples

Mulchers

Mulchers

Power Rakes

Power Rakes

Snow Pushers

Snow Pushers

Stump Grinders

Stump Grinders

BROOMS

BROOMS

BUCKETS

BUCKETS